Unveiling Excellence: Innovations in Men’s Hair Systems Manufacturing

Men’s hair systems have evolved significantly, offering sophisticated solutions to individuals experiencing hair loss. These innovative hairpieces, crafted in specialized manufacturing facilities, integrate advanced technology with meticulous craftsmanship to deliver natural-looking results. This blog explores the cutting-edge innovations in men’s hair systems manufacturing, highlighting how these advancements enhance quality, customization, and client satisfaction.

Understanding Men’s Hair Systems

Men’s hair systems, also known as toupees or hair prosthetics, are custom-made solutions designed to replicate the appearance and feel of natural hair. These systems provide versatility in styling, comfort in wear, and a boost to self-confidence for those dealing with hair loss.

The Evolution of Hair Systems Manufacturing

Hair system manufacturing has undergone significant advancements, revolutionizing the industry and improving the client experience. Let’s delve into the innovative technologies and processes that shape the creation of modern men’s hair systems:

Cutting-Edge Technologies and Processes

1. Computer-Aided Design (CAD)

CAD software plays a crucial role in designing and prototyping hair systems with unparalleled precision. Technicians use CAD to create detailed measurements, simulate hair placement, and customize base materials to match client specifications. This technology ensures consistency and accuracy in every hair system produced.

2. 3D Printing

3D printing technology has revolutionized the prototyping and production of base materials for hair systems. It allows for rapid iteration, precise customization of base designs, and the creation of complex structures that enhance comfort and natural appearance. 3D printing also reduces production time and waste, making it a sustainable choice for hair system manufacturing.

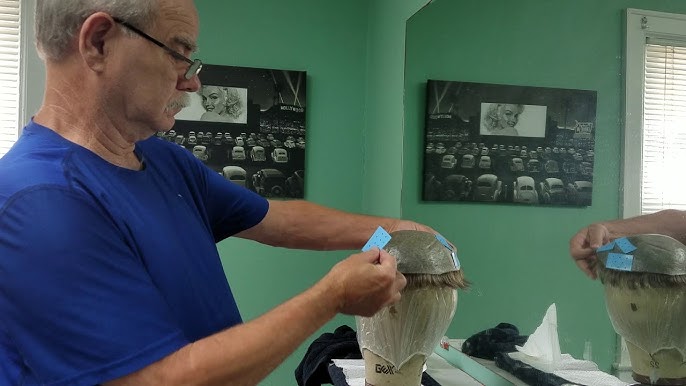

3. Ventilation Techniques

Innovative ventilation techniques ensure natural-looking hair distribution within the base material of hair systems. Advanced machinery and skilled craftsmanship enable technicians to achieve uniform hair density, realistic hairlines, and natural movement that mimic the characteristics of natural hair growth. These techniques enhance the overall aesthetic and comfort of the hair system.

4. Material Innovations

Hair system factory continually explore new materials and combinations to enhance durability, comfort, and aesthetic appeal. Innovations in base materials, such as lightweight polymers, breathable lace, and natural-looking monofilament, offer clients a range of options to suit their lifestyle and preferences. These materials contribute to the realism and longevity of the hair system.

5. Quality Control Processes

Stringent quality control measures ensure that every hair system meets the highest standards of craftsmanship and durability. Technicians conduct thorough inspections throughout the manufacturing process, from material selection to final styling, to identify and rectify any imperfections. This commitment to quality guarantees that clients receive a flawless product that exceeds expectations.

The Impact of Innovations on Client Satisfaction

The integration of cutting-edge technologies and processes in hair system manufacturing enhances client satisfaction in several ways:

- Customization: Clients can personalize their hair systems with precision-fit measurements, customized hair color and texture, and tailored base materials that suit their scalp and lifestyle.

- Natural Appearance: Advanced ventilation techniques and material innovations create hair systems that blend seamlessly with natural hair, providing a lifelike appearance and boosting confidence.

- Comfort and Durability: Lightweight materials and ergonomic designs enhance comfort and durability, allowing clients to wear their hair systems with ease and longevity.

- Efficiency: Improved production processes reduce lead times and ensure timely delivery of customized hair systems, meeting client expectations for quality and service.

Conclusion

Innovations in men’s hair systems manufacturing represent a synergy of creativity, technology, and client-centric focus. Hair system factories are at the forefront of transforming the industry with advanced techniques that enhance realism, comfort, and customization. From CAD design and 3D printing to innovative ventilation and material selections, these advancements redefine what is possible in restoring hair and confidence.

As technology continues to advance, the future holds promise for even more realistic, comfortable, and personalized men’s hair systems. For individuals considering a hair restoration solution, understanding the innovative processes behind each hair system can provide confidence in choosing a solution that meets their unique needs and exceeds expectations.

Investing in a men’s hair system isn’t just about restoring hair—it’s about embracing innovation and reclaiming confidence with a solution that reflects excellence in craftsmanship and technology.